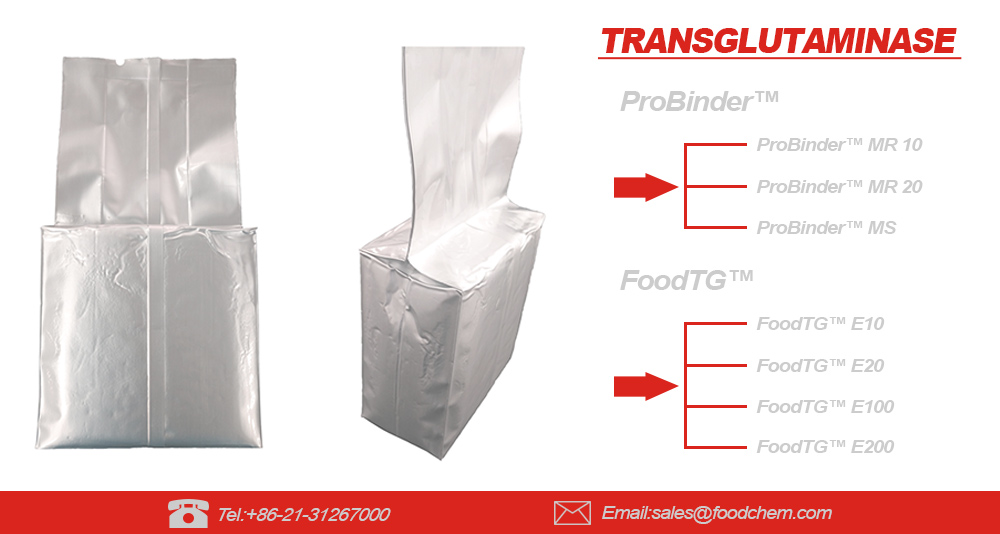

ProBinder™ MR20 [Transglutaminase abbreviation: TG & ProBinder™ MR20]

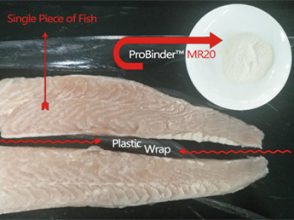

The ProBinder™ MR20 is usually sprinkled on the piece of meat to be bonded. Sprinkle enough MR20 on both surfaces to form complete dust; The brush spreads the coating evenly. Alternatively, immerse the debris directly into the MR20. The ProBinder™ MR20 can also be mixed with 4 parts by weight of ice water to form a slurry to coat the meat. The slurry must be used within 20 minutes because the adhesion in the ProBinder™ MR20 decreases over time, sodium caseinate will be combined with itself.

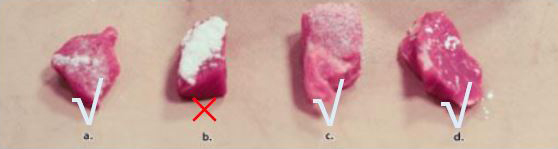

- [a] Sprinkle the correct amount of ProBinder™ MR20 from the bag

- [b] Too many ProBinder™ MR20 spilled from the bag

- [c] Easier to spill from the shaker

- [d] Apply ProBinder™ MR20:Cold water=1:4 slurry

Application of TG in meat products [Transglutaminase abbreviation: TG]

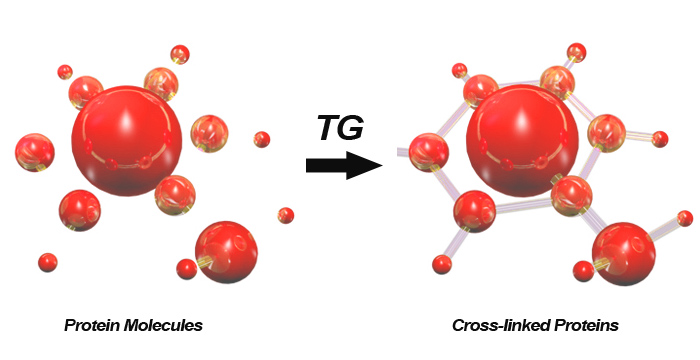

(1) TG can increase the binding force of protein in processed meat products, enhance the elasticity of meat products, improve the slicing performance, improve the tenderness of products, and improve the texture structure of meat products.

In the processing of meat products, the most basic raw material is animal muscle. Myosin and actomyosin are important components in muscle and play a key role in maintaining muscle water retention and adhesion. In the case of heat, a disulfide bond is formed between myosin molecules and between actomyosin molecules, and a complex heat-induced gel space network structure is formed under the interaction of molecular hydrophobic groups, and the disulfide bond And hydrophobic groups act as junctions on this network. The myofibrillar protein thermally induces the formation of a gel, which gives the meat product a quality characteristic such as elasticity, slicing, and water retention. Adding TG to the meat product, in addition to the above forces, can also form a ε-(r-glutamic acid) lysyl covalent bond in the muscle protein molecule, and this covalent bond has a strong force. It is 70 times more than disulfide bond energy, which can bind protein molecules more tightly, maintain the formation of muscle protein gel system, and improve the quality of meat products. Experiments show that the injection of ham with 0.1% TG is superior to the control product in product rupture strength and concavity.

(2) TG can partially replace the quality improver monophosphate added in the processing of meat products to produce low-salt meat products.

Salt, phosphate and nitrite are essential ingredients in the processing of various meat products and they play an important role in maintaining the quality of meat products. But their large additions imply the potential for health damage. Experiments have shown that the addition of TG to meat products can reduce the amount of these salts, while maintaining the original flavor of the meat products. For example, if the amount of salt in the sausage is reduced to 0.4%, and then 0.25% of TG is added, the bursting strength of the sausage is exactly the same as that of the sausage with 1.7% salt. Sausages with 0.3% phosphate were less resistant to cracking than sausages without phosphate plus 0.6% TG. Therefore, it can be confirmed that TG can fully play the role of phosphate additives in increasing the cohesion of intestinal filling and increasing water retention in meat products. At the same time, the application of TG can also produce excellent emulsifiers and develop low-fat health-care foods.

(3) TG can reorganize low-value minced meat to improve its appearance, structure and flavor to improve its nutritional value and utilization.

In the processing of meat products, a large amount of minced meat is produced. With TG, these pieces of meat can be reconstituted into whole pieces of meat, thereby improving the utilization rate of raw meat and reducing the production cost. Experiments have shown that the use of decomposed ground beef and fat (including fixed fat components) under the action of 0.2% to 0.5% TG, cross-linking between the thick chains of beef myogenic protein, can create a sense of export Good steak with a fixed nutrient.

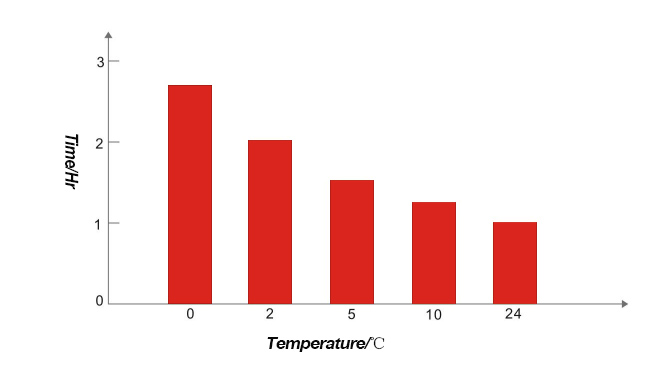

Relationship between enzyme reaction temperature and time

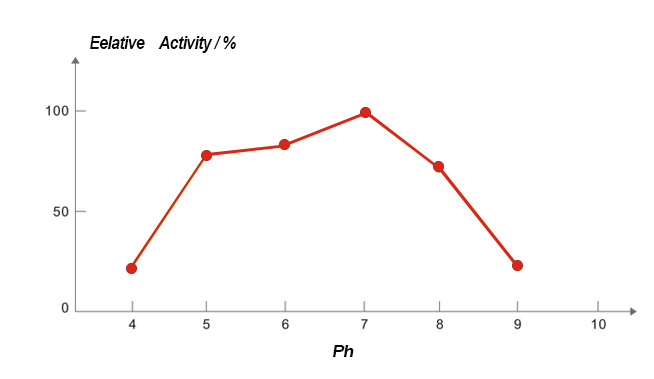

Transglutaminase catalyzes a reaction over a wide pH range

Optimum pH of TG is pH 7.0

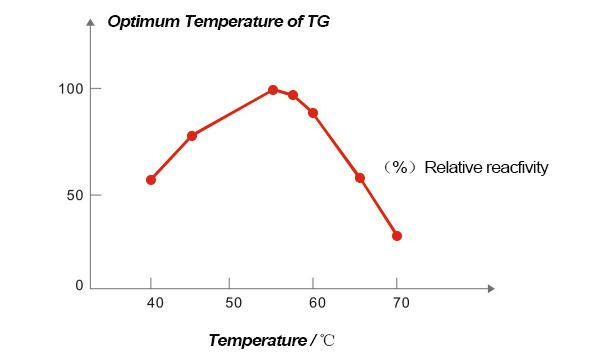

The optimum temperature of TG is about 55℃. It also has high activity in the range of 45℃-55℃, A major advantage of TG is that it becomes inactive when the internal temperature of food is at 75℃ or more in normal foods.

See more: https://www.foodchem.com/app_cat/meat/